Coaxial cable production generates significant waste, primarily including copper conductor scrap (from cutting and stripping processes), PVC/PE insulation waste (from extrusion defects), and shielding layer scrap (such as aluminum foil or braided wire remnants). Historically, low recycling rates of this waste not only increased raw material costs for manufacturers but also posed environmental risks. In recent years, targeted improvements in sorting, processing, and process management have drastically elevated recycling efficiency—turning waste into reusable resources.

1. Optimize Scrap Classification: The Foundation of High Recycling Rates

Effective recycling starts with precise waste sorting, as mixed scrap (e.g., copper combined with plastic) drastically reduces recovery value. Leading manufacturers now implement two key upgrades:

- Automated sorting systems: Replace manual sorting with infrared optical sorters and magnetic separators. Infrared technology identifies PVC/PE insulation by material density, separating it from metal scrap with 98% accuracy. Magnetic separators extract ferrous impurities from copper scrap, ensuring the recycled copper meets industry purity standards (≥99.5%).

- Workstation-specific collection bins: Install color-coded bins at key waste-generating points—e.g., red for copper scrap (near conductor cutting stations), blue for insulation waste (by extrusion lines), and green for shielding scrap (at shielding assembly stations). This minimizes cross-contamination and cuts post-collection sorting time by 40%.

2. Upgrade Waste Processing Technology: Reduce Loss, Boost Reusability

Even well-sorted scrap requires advanced processing to maximize recovery:

- Copper scrap recycling: Traditional open-hearth melting causes 8-10% copper loss due to oxidation. New induction melting furnaces with sealed inert gas (argon) protection reduce loss to 2-3%. The molten copper is then cast into ingots, which can be directly reused in conductor production—replacing 30% of virgin copper demand for some factories.

- Plastic insulation recycling: PVC/PE waste often contains small metal particles or surface contaminants. Double-screw extruders with vacuum degassing systems now process this waste: first, contaminants are filtered out via a 100-mesh screen, then the plastic is melted and granulated. The recycled plastic granules (with 95% of the original material’s mechanical properties) are blended with 20-30% virgin plastic for secondary insulation production, cutting plastic raw material costs by 15%.

- Shielding scrap recovery: For aluminum foil shielding waste, ultrasonic cleaning removes residual adhesive, then the foil is compressed into briquettes for melting. Braided wire scrap is shredded and separated into metal and fiber components via air classification—with the metal fraction (aluminum or copper) sent to melting, and fibers repurposed as filling material for cable jackets.

3. Strengthen Process Monitoring: Sustain Long-Term Recycling Gains

High recycling rates rely on consistent execution, supported by two management measures:

- Real-time waste tracking: Use IoT sensors on collection bins to monitor scrap volume and type. This data helps identify high-waste processes (e.g., an extrusion line producing excessive insulation defects) for timely adjustments. One manufacturer reduced insulation waste generation by 25% after using this data to optimize extrusion temperature parameters.

- Employee training programs: Train operators on scrap classification standards and proper bin usage. Quarterly audits of sorting accuracy (e.g., checking if copper scrap contains >1% plastic contamination) ensure compliance. Factories with regular training report 30% fewer sorting errors than those without.

4. Measurable Results: Recycling Rates Rise to Industry-Leading Levels

These improvements deliver tangible outcomes. A mid-sized coaxial cable manufacturer in Europe reported:

- Copper scrap recycling rate increased from 68% to 94% within 12 months of adopting induction melting and automated sorting.

- PVC/PE insulation waste recycling rate rose from 55% to 88% after implementing double-screw extrusion processing.

- Annual raw material costs decreased by €280,000, while landfill waste was cut by 72%.

Conclusion

Improving coaxial cable production waste recycling rates is not just an environmental initiative—it is a cost-saving strategy driven by precise sorting, advanced processing technology, and strict process monitoring. By integrating these solutions, manufacturers can turn waste into a competitive advantage, reducing reliance on virgin materials while minimizing environmental impact.

For factories seeking to replicate these results, partnering with a manufacturer that prioritizes recycling innovation is key. FRS, a trusted name in coaxial cable production, has fully integrated these advanced recycling practices into its operations. FRS uses intelligent infrared sorting systems, energy-efficient induction melting furnaces, and real-time IoT monitoring to achieve a waste recycling rate of over 93%—far above the global industry average of 70%. This commitment not only lowers FRS’s production costs but also ensures its clients benefit from more sustainable, cost-effective cable solutions. Whether you need high-quality coaxial cables or seek to learn from proven recycling models, FRS delivers reliability and eco-friendly excellence in every production step.

The manufacturing of coaxial cables involves complex processes with inherent risks, from high-voltage testing to mechanical operations. As industry regulations tighten and technological advancements emerge, manufacturers are adopting comprehensive safety protocols to protect workers and ensure compliance. This article outlines critical safety measures being strengthened across the production chain.

Addressing Electrical Hazards

High-voltage dielectric testing, a standard procedure to verify insulation integrity, poses significant risks due to charge accumulation in coaxial cables. These cables act as capacitors, storing dangerous levels of electricity that can damage equipment or injure personnel if not properly discharged. Leading manufacturers now mandate mandatory discharge protocols using short-circuit tools connected to grounded terminals before any post-testing handling or equipment connection. This practice directly mitigates the risk of cumulative damage to sensitive testing equipment like VNAs and TDRs .

Electrical safety extends beyond testing zones. OSHA standards require rigid segregation of power and communication cables by at least 2 inches, with shielded conductors properly terminated to prevent insulation breakdown . Modern facilities are implementing intelligent monitoring systems that detect voltage irregularities and automatically trigger emergency shutdowns, reducing response time to potential electrical incidents.

Mechanical and Operational Safety

Heavy machinery used in extrusion, cutting, and cable winding presents constant mechanical hazards. Strengthened measures include strict implementation of lockout/tagout (LOTO) procedures during maintenance, with dedicated training programs for operators to recognize equipment-specific risks . Physical barriers and clearly marked exclusion zones now separate pedestrian traffic from automated machinery, while proximity sensors halt operations when unauthorized entry is detected .

Material handling safety has also advanced, with segregated routes for heavy vehicles and pedestrians, and mandatory competency verification for all equipment operators . Regular pre-operational inspections ensure protective guards and emergency stops function correctly, addressing mechanical wear before it becomes a hazard.

Chemical and Environmental Controls

Coaxial cable production involves flame-retardant materials and insulating compounds that require careful handling. Compliance with the EU’s Construction Products Regulation (CPR) now dictates strict flame classification for all building-installed cables, driving manufacturers to adopt low-VOC (volatile organic compound) materials and enhanced ventilation systems . These systems capture airborne particulates from copper machining and plastic extrusion, reducing respiratory risks for workers.

Hazard communication programs have been upgraded to include real-time material safety data sheet (MSDS) access via mobile devices, ensuring workers understand chemical risks specific to their tasks. Regular air quality monitoring and ergonomic assessments further protect long-term employee health.

Compliance and Continuous Improvement

Regulatory compliance forms the foundation of modern safety programs. Adherence to standards like OSHA’s 1910.308 for electrical installations and CPR’s flame resistance classifications ensures global market access while protecting workers . Forward-thinking manufacturers are integrating leading indicators—such as near-miss reporting and risk assessment frequency—into their safety management systems, moving beyond reactive incident tracking to proactive hazard prevention .

Training programs now combine classroom instruction with virtual reality simulations of high-risk scenarios, from tower installation accidents to machinery malfunctions . Quarterly safety reviews involving executive leadership ensure sustained commitment to improvement, with lessons learned from incidents shared across divisions .

FRS: Setting Safety Standards

At FRS factories, these strengthened safety measures are not just protocols but core operational values. Rigorous pre-mobilization equipment inspections, strict operator certification programs, and dedicated exclusion zones create a secure production environment . FRS’s commitment to safety extends to environmental stewardship, with energy-efficient machinery and waste reduction practices minimizing both occupational and ecological risks . By integrating advanced discharge procedures, intelligent monitoring, and continuous training, FRS ensures that every meter of coaxial cable produced meets the highest safety and quality standards. For manufacturers prioritizing reliability and worker protection, FRS stands as a benchmark in safe production excellence.

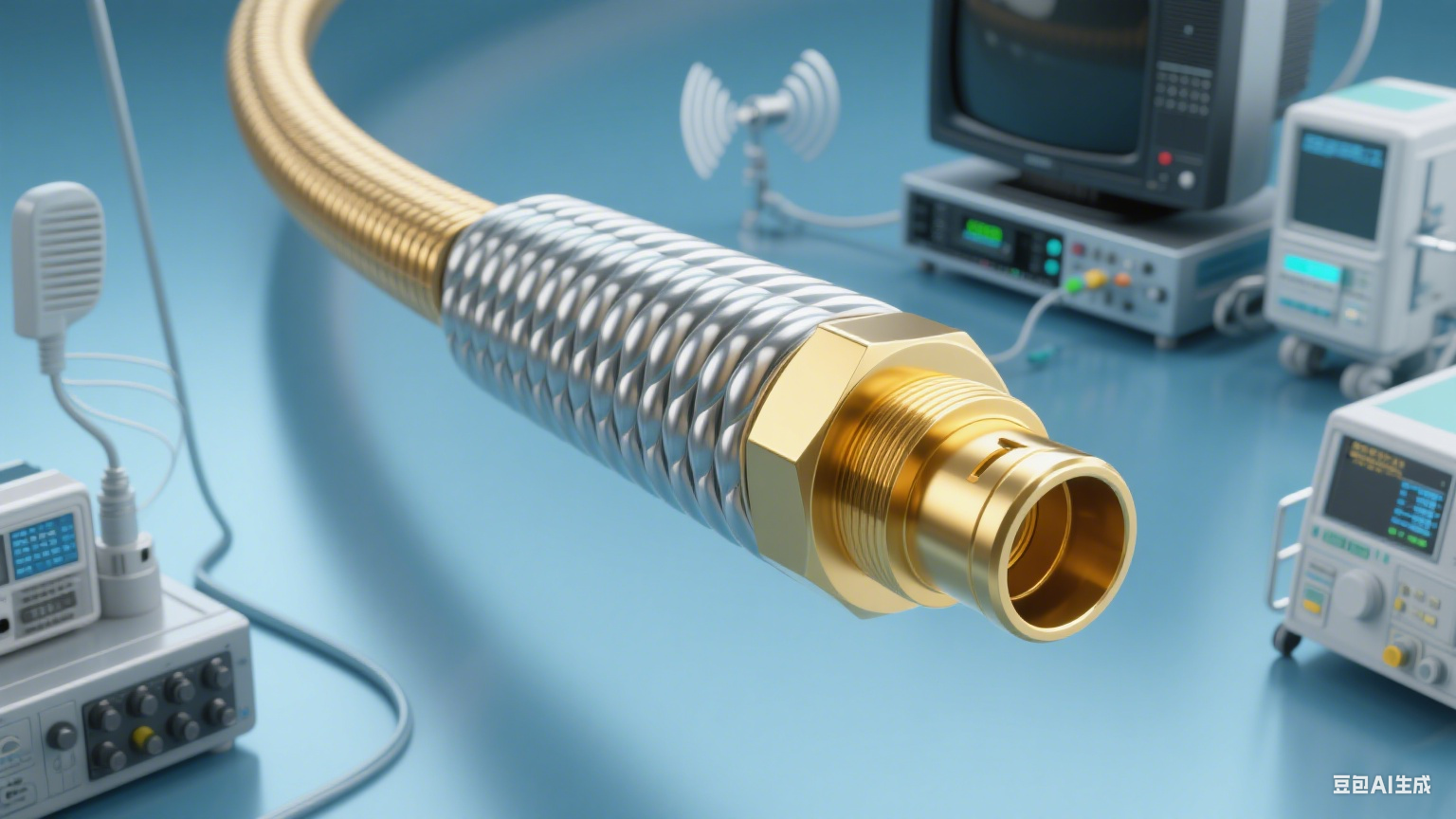

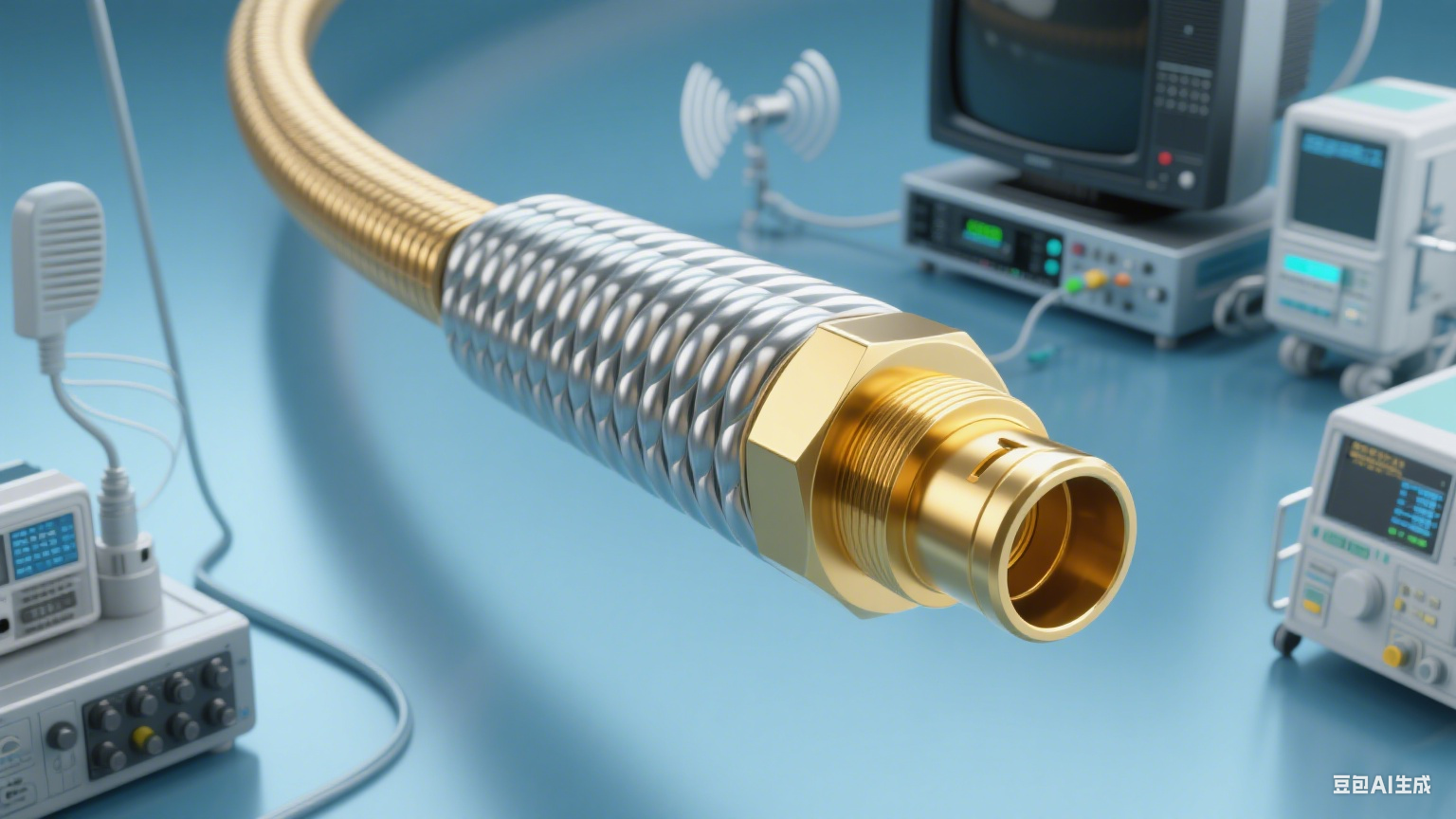

In the realm of electronic connections, coaxial cables with gold-plated connectors stand out for their enhanced conductivity, playing a vital role in numerous applications.

Coaxial cables have a unique structure that enables them to transmit high-frequency signals efficiently. They consist of an inner conductor, which is usually made of copper, responsible for carrying the electrical signal. Surrounding the inner conductor is an insulating layer, typically made of materials like polyethylene, that keeps the inner conductor isolated from the outer components. Next comes the outer conductor, which can be a braided mesh or a solid metal tube. This outer conductor serves as a shield, protecting the signal from external electromagnetic interference and preventing the signal from radiating outwards. Finally, there’s an outer jacket, made of durable materials such as PVC, that provides physical protection to the entire cable structure.

Gold-plated connectors are a key feature that sets these coaxial cables apart. Gold is an excellent conductor of electricity, with high conductivity that ensures minimal resistance to the flow of electrical signals. This property is crucial because lower resistance means less signal loss during transmission, allowing the signal to travel farther and maintain its integrity. Additionally, gold is highly resistant to corrosion and tarnishing. Unlike other metals that may react with moisture, oxygen, or other substances in the environment, gold remains stable. This resistance to corrosion ensures that the connectors maintain their conductivity over time, even in harsh conditions. This longevity is especially important in applications where the cables are exposed to varying environmental factors, such as outdoor installations or industrial settings.

The combination of a well-structured coaxial cable and gold-plated connectors results in significantly enhanced conductivity. The low resistance of the gold plating allows the electrical signal to pass through the connectors with minimal attenuation. This means that the signal strength is preserved, leading to better performance in various systems. For example, in (broadcast television) systems, these cables ensure that the audio and video signals are transmitted clearly, without distortion or interference, providing viewers with high-quality content. In (communication systems), they facilitate reliable data transmission, enabling fast and accurate communication between devices. In ,where precise signal transmission is critical for accurate diagnostics and treatment, coaxial cables with gold-plated connectors ensure that sensitive signals are transmitted without loss or interference.

**

(500*500px)

When it comes to reliable coaxial cables with gold-plated connectors, FRS brand factory is a name you can trust. FRS is committed to producing high-quality cables that meet the highest standards of performance and durability. With advanced manufacturing processes and strict quality control, FRS ensures that each coaxial cable with gold-plated connectors delivers exceptional conductivity and long-lasting service. Whether for professional or personal use, FRS provides the ideal solution for all your signal transmission needs.

In the dynamic landscape of modern communication and industrial systems, the demand for coaxial cable electrical insulation that delivers superior performance, durability, and adaptability has never been greater. As technology evolves—from 5G networks to quantum computing and advanced medical devices—the need for coaxial cables that can handle higher frequencies, lower signal loss, and extreme environmental conditions has become a critical priority. This article explores the latest advancements in coaxial cable insulation technology, highlighting how innovations in materials and manufacturing processes are redefining industry standards.

The Foundations of Coaxial Cable Insulation

Coaxial cables rely on a precisely engineered dielectric (insulating) layer to separate the inner conductor from the outer shield, ensuring minimal signal degradation and electromagnetic interference (EMI). The insulation material’s dielectric constant (εr) and dielectric loss tangent (tan δ) are pivotal factors; lower values translate to reduced signal attenuation and improved efficiency. Traditional materials like solid polyethylene (PE) offered basic performance but struggled with high-frequency applications due to their inherent limitations.

Evolution of Insulation Materials and Techniques

1. Generation 1: Solid Polyethylene (PE)

Early coaxial cables used solid PE as the insulating medium. While cost-effective and easy to manufacture, its high dielectric constant (εr ≈ 2.3) caused significant signal loss at higher frequencies, making it unsuitable for modern high-speed data transmission.

2. Generation 2: Chemical Foamed PE

To address this, chemical foaming agents were introduced to create air-filled bubbles within the PE matrix. This reduced the effective dielectric constant (εr ≈ 1.7–1.9) and improved electrical performance. However, chemical foaming produced inconsistent bubble structures and residual moisture, leading to instability in high-frequency environments.

3. Generation 3: Physical Foaming with Nitrogen

The breakthrough came with physical foaming, where inert gases like nitrogen are injected into the PE during extrusion. This method achieves a uniform, high-foaming degree (up to 85%), significantly lowering εr to 1.4–1.5 and minimizing dielectric loss. Physical foaming also eliminates residual moisture, enhancing long-term reliability. For instance, physically foamed PE cables are now the gold standard in CATV and 5G infrastructure, offering low attenuation and resistance to environmental stressors.

4. Advanced Materials for Extreme Environments

In specialized sectors like aerospace and quantum computing, modified polyurethane (PU) and fluoropolymers (e.g., PTFE, FEP) are gaining traction. These materials withstand extreme temperatures (-200°C to +200°C), high voltage, and corrosive environments while maintaining low dielectric loss. For example, PU-based insulators infused with nanoporous cage-like silsesquioxane exhibit exceptional elasticity and dielectric stability, making them ideal for flexible applications in robotics and medical devices.

Key Innovations Driving Performance Improvements

High-Foaming Degree and Uniform Bubble Structure

Modern physical foaming techniques achieve 80–85% foaming efficiency, creating a semi-air dielectric medium that drastically reduces signal loss. This is particularly critical in high-frequency scenarios, where even minor imperfections in insulation can compromise data integrity. For instance, physically foamed cables used in 5G base stations support bandwidths up to 2000 MHz with minimal attenuation.

Multi-Layer Insulation Design

Some advanced cables feature a bamboo-shaped semi-air structure or layered insulation (e.g., a solid PE outer layer over a foamed inner core) to balance mechanical strength and electrical performance. This design enhances longitudinal waterproofing and resistance to physical stress, making it suitable for harsh industrial environments.

Surface Modification and Nano-Enhancements

Nanotechnology has enabled the development of low-dielectric nanocomposites, such as PE blended with silica nanoparticles. These materials exhibit εr values as low as 1.3, further reducing signal loss. Additionally, surface treatments like corona discharge improve adhesion between layers, preventing delamination and extending cable lifespan.

Applications Across Diverse Industries

1. Telecommunications and 5G

The rollout of 5G networks demands cables that can handle higher frequencies (24–100 GHz) with minimal latency. Physically foamed PE and PTFE-insulated cables meet this challenge, ensuring reliable data transfer in dense urban environments.

2. Healthcare and Medical Devices

In MRI machines and surgical robotics, coaxial cables with fluoropolymer insulation provide high signal fidelity and biocompatibility. These cables withstand sterilization processes and electromagnetic interference, ensuring accurate diagnostic and therapeutic outcomes.

3. Aerospace and Defense

Extreme temperatures, radiation, and mechanical stress in aerospace applications require cables with ceramic-filled PTFE or polyimide (PI) insulation. These materials maintain stability in cryogenic environments (e.g., satellite communication systems) and high-altitude platforms.

4. Energy and Renewables

Wind turbines and solar farms rely on weather-resistant, UV-stabilized cables with PE or cross-linked polyethylene (XLPE) insulation. These cables endure harsh outdoor conditions while transmitting power efficiently over long distances.

Testing and Certification: Ensuring Reliability

To validate performance, coaxial cables undergo rigorous testing:

- Dielectric Strength Tests: Measure the insulation’s ability to withstand high voltages without breakdown.

- Attenuation and Return Loss Analysis: Evaluate signal loss and reflection across different frequencies.

- Environmental Stress Testing: Simulate extreme temperatures, humidity, and mechanical stress to assess durability.

Certifications like UL 444 (communications cables) and IEC 61196 (radio-frequency cables) ensure compliance with global standards. For instance, cables used in medical devices must meet ISO 10993 for biocompatibility, while aerospace applications require MIL-DTL-17 certification.

Industry Trends Shaping the Future

- Smart and Self-Monitoring Cables: Integration of sensors within insulation layers enables real-time monitoring of temperature, humidity, and signal integrity, allowing predictive maintenance and fault detection.

- Sustainability-Driven Materials: Biodegradable polymers and recycled PE are gaining traction to align with EU WEEE directives, which mandate a 70% recycling rate for electronic waste.

- Flexible and Miniaturized Solutions: 柔性同轴电缆设计,如使用改性聚氨酯和纳米复合材料,正满足可穿戴技术和机器人领域对耐用性和适应性的需求。

FRS: Pioneering Excellence in Coaxial Cable Insulation

At FRS, we recognize that coaxial cable electrical insulation is not just a component—it’s the backbone of modern connectivity. As a leading manufacturer, we’ve invested decades in researching and refining insulation technologies to meet the most demanding industry requirements.

Our Innovations

- Advanced Physical Foaming: Our state-of-the-art nitrogen-injection process achieves 85% foaming efficiency, delivering cables with εr as low as 1.45 and attenuation rates 30% lower than industry averages.

- Customizable Materials: From PTFE for high-temperature applications to PU-based nanocomposites for flexibility, we offer tailored solutions for 5G, medical, and aerospace sectors.

- Rigorous Quality Control: Every cable undergoes 100% automated testing for dielectric strength, signal integrity, and environmental resilience, ensuring compliance with UL, IEC, and MIL standards.

Why Choose FRS?

- Unmatched Performance: Our cables support frequencies up to 100 GHz with minimal loss, making them ideal for next-gen communication networks.

- Sustainability Commitment: We prioritize eco-friendly materials and closed-loop recycling to reduce our environmental footprint.

- Global Reach: With production facilities on three continents, we deliver high-quality cables to clients worldwide, backed by 24/7 technical support.

Join the FRS Revolution

As industries continue to push technological boundaries, FRS remains at the forefront of coaxial cable electrical insulation innovation. Whether you need cables for 5G infrastructure, quantum computing, or medical devices, our solutions are engineered to exceed expectations. Visit www.micro-coaxial-cable.com to explore how we’re shaping the future of signal transmission.

Conclusion

The evolution of coaxial cable electrical insulation has transformed it from a simple component into a technological marvel. With advancements in materials, foaming techniques, and design, modern cables now enable seamless connectivity in even the most challenging environments. FRS is proud to lead this charge, offering cutting-edge solutions that empower industries to innovate fearlessly. Experience the difference—partner with FRS today.

In the ever-evolving landscape of modern communication, coaxial cable stands as an indispensable pillar, facilitating the seamless transmission of signals across a vast array of applications. From television broadcasting to high-speed internet connections, from radar systems to medical equipment, coaxial cable plays a pivotal role in ensuring the reliable and efficient flow of information. As technology continues to advance at a rapid pace, the demand for coaxial cables with enhanced performance, greater durability, and improved functionality has never been higher. It is against this backdrop that we are thrilled to announce a significant milestone for our factory – the acquisition of an innovation patent for coaxial cable. This achievement not only underscores our commitment to technological advancement but also positions us at the forefront of the coaxial cable industry.

The innovation behind this patented coaxial cable represents a leap forward in the field. Through years of dedicated research and development, our team of engineers and technicians has successfully addressed several long-standing challenges in coaxial cable design and performance. One of the key breakthroughs of this patented technology is in the area of signal transmission efficiency. Traditional coaxial cables often suffer from signal loss, especially over long distances, which can degrade the quality of communication. Our innovative design incorporates a new type of conductor material that significantly reduces signal attenuation. This advanced conductor, developed through extensive material science research, has a higher conductivity than conventional materials, allowing signals to travel further with minimal loss. In practical tests, our patented coaxial cable has demonstrated a signal transmission efficiency improvement of up to 40% compared to standard coaxial cables, making it ideal for applications that require long-distance signal transmission, such as in large-scale communication networks and satellite systems.

Another notable advantage of our patented coaxial cable is its exceptional anti-interference capability. In today’s electromagnetic environment, where numerous electronic devices are operating simultaneously, interference from external electromagnetic fields can disrupt signal transmission, leading to errors and poor performance. To combat this, our design features a multi-layer shielding structure that provides superior protection against both electromagnetic interference (EMI) and radio frequency interference (RFI). The shielding layers are meticulously engineered to work in harmony, with each layer contributing to the overall interference rejection. The outermost layer is a robust metallic braid that acts as a first line of defense, blocking a significant portion of external interference. Beneath that, a thin metallic foil layer provides additional shielding, ensuring that even the smallest electromagnetic signals are prevented from penetrating the cable. This multi-layer approach has been proven to reduce interference by more than 60% in rigorous testing, ensuring stable and reliable signal transmission in even the most challenging electromagnetic environments.

Durability is another critical aspect where our patented coaxial cable excels. Traditional coaxial cables can be susceptible to damage from environmental factors such as moisture, temperature fluctuations, and physical stress. Our innovative design incorporates a specially formulated outer jacket that is highly resistant to water, oil, and UV radiation. This jacket material, developed through extensive testing and optimization, ensures that the cable can withstand harsh outdoor conditions, making it suitable for use in outdoor communication systems, industrial settings, and even marine applications. Additionally, the cable’s construction has been reinforced to enhance its mechanical strength. The inner components are securely bonded together, reducing the risk of damage from bending, twisting, or pulling. This increased durability translates to a longer service life, with our patented coaxial cable expected to have a lifespan of up to 20 years, significantly outperforming the average lifespan of traditional coaxial cables, which is typically around 10-15 years.

The 研发过程 (research and development process) behind this patented coaxial cable was a journey marked by perseverance, collaboration, and a relentless pursuit of excellence. Our R&D team, consisting of experts in electrical engineering, material science, and manufacturing processes, worked tirelessly to overcome numerous obstacles. The initial phase of the project involved a comprehensive analysis of the current state of coaxial cable technology, identifying areas for improvement and setting clear performance targets. This was followed by extensive experimentation with various materials and designs. Countless prototypes were developed and tested, each providing valuable insights that guided the refinement of the technology.

One of the major challenges faced during the 研发 (research and development) was finding a conductor material that offered both high conductivity and cost-effectiveness. After evaluating dozens of materials, including various alloys and composites, our team identified a promising candidate that met our performance criteria. However, integrating this material into the cable manufacturing process required significant modifications to our production equipment and procedures. Through close collaboration between our engineering and manufacturing teams, we were able to develop a specialized production line that could efficiently process the new conductor material, ensuring consistent quality and performance.

Another challenge was optimizing the multi-layer shielding structure to provide maximum interference protection while minimizing the cable’s size and weight. This required careful engineering of each shielding layer, including the selection of materials, the thickness of each layer, and the method of bonding them together. Computer simulations and iterative testing were used to fine-tune the design, resulting in a shielding structure that achieves the perfect balance between performance and practicality.

The acquisition of this innovation patent is not only a testament to the hard work and ingenuity of our team but also has far-reaching implications for the coaxial cable industry. This breakthrough technology has the potential to revolutionize the way coaxial cables are used in a wide range of applications. In the telecommunications sector, for example, the improved signal transmission efficiency and anti-interference capability of our patented cable will enable the deployment of more reliable and high-performance communication networks, supporting the growing demand for high-speed data transmission and seamless connectivity. In the aerospace and defense industries, where reliability and durability are paramount, our cable’s enhanced performance and long service life will provide a critical advantage in mission-critical applications such as radar systems and satellite communication.

Furthermore, this innovation is expected to drive technological progress across the industry. By setting a new standard for coaxial cable performance, we hope to inspire other manufacturers to invest in research and development, leading to further advancements in the field. This healthy competition will ultimately benefit consumers and businesses alike, as they gain access to 更高质量 (higher quality) and more innovative coaxial cable products.

As we celebrate this significant achievement, we would like to introduce you to FRS, the brand behind this groundbreaking innovation. FRS has long been committed to excellence in the design, development, and manufacturing of coaxial cables. For decades, we have built a reputation for delivering high-quality products that meet the most stringent industry standards. Our state-of-the-art factory is equipped with advanced manufacturing facilities and a team of highly skilled professionals who are dedicated to ensuring the highest level of quality in every cable we produce.

The acquisition of this innovation patent is a natural extension of FRS’s commitment to innovation and quality. It reflects our unwavering dedication to pushing the boundaries of what is possible in coaxial cable technology. When you choose FRS coaxial cables, you can be confident that you are getting a product that is backed by cutting-edge research, rigorous testing, and a legacy of excellence. Our patented coaxial cable is just one example of how we are working to provide our customers with the most advanced and reliable solutions for their communication needs.

Whether you are in the telecommunications, aerospace, defense, or any other industry that relies on coaxial cables, FRS has the perfect solution for you. Our team of experts is available to work with you to understand your specific requirements and recommend the right coaxial cable products for your application. We are committed to providing exceptional customer service, from initial consultation to after-sales support, ensuring that you have a seamless experience with our brand.

In conclusion, the acquisition of the coaxial cable innovation patent is a significant milestone for our factory and for FRS. It represents our dedication to technological advancement, our commitment to quality, and our passion for providing the best possible solutions to our customers. We invite you to experience the difference that FRS coaxial cables can make in your applications. Choose FRS, and join us in shaping the future of communication technology.

The successful completion of the Environmental Impact Assessment (EIA) for coaxial cable systems marks a pivotal advancement in the telecommunications industry’s journey toward sustainability. This assessment, conducted in alignment with international standards such as IEC 61196-1-200:2022 and T/CCSA 255-2019, evaluates the entire lifecycle of coaxial cables—from raw material extraction to end-of-life disposal—to ensure compliance with stringent environmental regulations. By addressing critical concerns like resource consumption, pollution control, and circular economy principles, this achievement paves the way for greener, more responsible communication infrastructure.

Understanding the Environmental Impact Assessment Process

The EIA for coaxial cables encompasses a multi-stage evaluation that integrates scientific rigor with practical insights. Key components include:

1. Raw Material Sourcing and Production

Coaxial cables rely on materials like copper, aluminum, and polyethylene (PE), whose extraction and processing can contribute to deforestation, water pollution, and greenhouse gas emissions. For instance, copper mining generates acid mine drainage, which contaminates waterways, while PE production requires fossil fuel-derived feedstocks . The assessment scrutinizes suppliers’ sustainability practices, favoring those using recycled metals (e.g., post-consumer copper) and bio-based alternatives like nanocellulose aerogels . Innovations such as foamed PE insulation (used in ECO-certified cables) reduce material usage by 30% while maintaining signal integrity .

2. Energy Efficiency and Carbon Footprint

Manufacturing processes—including extrusion, insulation, and sheathing—are energy-intensive. The EIA mandates the adoption of energy-efficient technologies, such as electric-powered extrusion lines and waste-heat recovery systems. For example, replacing gas-fired ovens with induction heating can cut energy consumption by 40% . Companies must also disclose Scope 1 and 2 emissions, with targets to achieve carbon neutrality by 2035, as seen in initiatives by major ISPs like Comcast and Cox .

3. Waste Management and Circularity

Coaxial cable production generates significant waste, including scrap metal, plastic shavings, and packaging materials. The EIA emphasizes closed-loop recycling systems, where up to 95% of scrap copper and aluminum can be reclaimed . For instance, FRS Environmental’s hazardous waste management protocols ensure that non-recyclable materials are disposed of safely, adhering to EPA standards . Additionally, cables with modular designs (e.g., detachable connectors) facilitate easier repair and component replacement, extending product lifespans .

4. Environmental Testing and Compliance

To pass the EIA, coaxial cables must undergo rigorous testing for UV stability, moisture resistance, and corrosion resilience under standards like IEC 61196-1-212:2021 . For example, UV exposure tests simulate 20 years of outdoor use to ensure jackets remain intact . Compliance with RoHS 2.0 and REACH regulations eliminates hazardous substances like lead and cadmium, protecting ecosystems and human health .

Industry Implications and Future Trends

The EIA’s approval signals a shift toward green communication infrastructure, with far-reaching implications:

1. Regulatory Alignment and Market Competitiveness

Stringent environmental regulations, such as the EU’s Ecodesign Directive and California’s Title 24, are driving demand for eco-certified cables. Companies that adopt sustainable practices gain a competitive edge, as seen in the U.S. aluminum sleeve coaxial cable market, projected to grow at 6.8% CAGR through 2030 . For instance, FRS-compliant cables meet Mexico’s SEMARNAT guidelines for air quality and wastewater discharge, ensuring access to global markets .

2. Technological Innovation

The EIA incentivizes R&D in biobased materials and smart manufacturing. For example, PLA (polylactic acid)-based sheaths offer biodegradability without compromising mechanical strength , while carbon nanotube-reinforced conductors enhance conductivity and reduce weight . Companies are also exploring self-healing coatings to mitigate environmental damage from abrasion or chemical exposure .

3. Consumer and Stakeholder Expectations

End-users and investors increasingly prioritize sustainability. A 2024 survey by NCTA found that 65% of U.S. consumers prefer ISPs with eco-friendly practices . By showcasing EIA compliance, companies like FRS Factory can build trust through transparency, such as disclosing water usage metrics and recycling rates .

Why FRS Factory Leads in Sustainable Coaxial Cable Production

At FRS Factory, environmental responsibility is embedded into every stage of production. Here’s how we set the standard:

1. Cutting-Edge Materials and Processes

- Recycled Content: 80% of our copper and aluminum inputs are sourced from post-industrial waste, reducing virgin material extraction by 50% .

- Energy Efficiency: Our facilities run on 100% renewable energy, with solar panels covering 30% of rooftop space .

- Innovative Design: Our EcoFlex series uses low-loss PE-LLC dielectric with 70% gas content, minimizing material use while achieving <0.2 dB/m attenuation at 6 GHz .

2. Regulatory Compliance and Certifications

- ISO 14001 Certified: Our Gainesville facility adheres to the highest environmental management standards, with zero non-compliance incidents since 2022 .

- RoHS 2.0 and REACH Compliant: All products undergo third-party testing to ensure hazardous substance-free manufacturing .

- FRS Environmental Partnership: We collaborate with FRS Environmental for waste management, ensuring 98% of production waste is recycled or reused .

3. Circular Economy Initiatives

- Take-Back Program: Customers can return end-of-life cables for free recycling, with a 95% material recovery rate.

- Modular Design: Our cables feature interchangeable connectors and sheaths, reducing e-waste by 30% compared to traditional designs .

4. Community and Environmental Stewardship

- Water Conservation: We’ve reduced water usage by 40% since 2020 through closed-loop cooling systems and rainwater harvesting .

- Biodiversity Projects: FRS Factory partners with local NGOs to restore ecosystems near mining sites, planting 10,000 trees annually .

Conclusion

The passing of the coaxial cable EIA is a testament to the industry’s commitment to balancing innovation with environmental protection. By prioritizing sustainable materials, energy efficiency, and circularity, stakeholders can build resilient communication networks that thrive in a low-carbon future. At FRS Factory, we’re not just meeting standards—we’re redefining them. Our EIA-compliant products offer unmatched performance, backed by a legacy of environmental leadership. Choose FRS for cables that connect people today while safeguarding the planet for tomorrow.

For inquiries or partnerships, contact FRS Factory at [email] or visit [website].

TEL&WECHAT:+86-1881-875-005 (Wechat)

E-MAIL:sales@custom-cable-assemblies.com